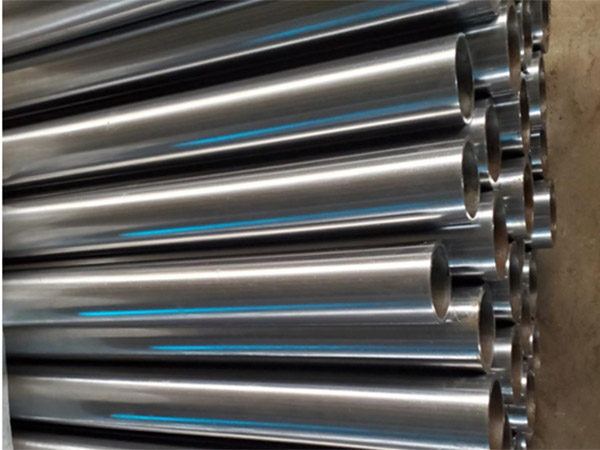

Moetsi oa Letlapa la Ts'epe le rekisoang

Lintlha

Bophara ba lakane ke 500 ~ 1500 mm;Bophara ba botenya ke 600 ~ 3000 mm.Lipoleiti tse tšesaane li arotsoe ka mefuta ea tšepe, ho kenyelletsa le tšepe e tloaelehileng, tšepe ea boleng bo holimo, tšepe ea alloy, tšepe ea selemo, tšepe e sa hloekang, tšepe ea lisebelisoa, tšepe e sa keneleng mocheso, tšepe ea silicon le lakane e hloekileng ea indasteri, joalo-joalo Ho ea ka setsebi. sebelisa, ho na le moqomo oa oli ka boto, enamel e nang le boto, bulletproof ka boto, joalo-joalo Ho ea ka lintlha tsa ho roala holim'a metsi, ho na le lakane e nang le galvanized, tin plate, lead plate, polasetiki e entsoeng ka tšepe e kopantsoeng.Mocheso o phahameng, khatello e phahameng, mocheso o tlase, ho hanyetsa kutu.

Lipoleiti tse teteaneng tsa tšepe li batla li lekana le tse tšesaane.Likarolong tsohle, ho kenyeletsoa poleiti ea borokho, poleiti ea boiler, tšepe ea likoloi, tšepe ea sejana sa khatello le tšepe ea tšepe ea multilayer e phahameng le mefuta e meng ke poleiti e teteaneng, mefuta e meng ea tšepe joalo ka poleiti ea tšepe ea koloi (2.5 ~ 10 mm botenya. ), poleiti ea mohlala e khabisitsoeng (2.5 ~ 8 mm thick), tšepe e sa hloekang, tšepe e sa keneleng mocheso le mefuta e meng e nang le sefapano se tšesaane.

Ho phaella moo, poleiti ea tšepe le thepa e boletse, hase lipoleiti tsohle tsa tšepe tse tšoanang, thepa ha e tšoane, sebaka seo ho sebelisoa tšepe ea tšepe, ha se tšoane.

Classification Of Alloy Steel

Ho ea ka litaba tsa likarolo tsa alloying, li ka aroloa ka:Tšepe ea alloy e tlase (kakaretso ea motsoako o ka tlase ho 5%), tšepe e bohareng ea alloy (kakaretso ea motsoako oa 5% -10%), tšepe e phahameng ea alloy (kakaretso ea motsoako oa motsoako> 10%).

Ho ea ka likarolo tse kholo tsa alloying, li arotsoe ka:Chromium steel (CR-Fe-C) Chrome-Nickel steel (CR-Ni-Fe-C), Manganese (Mn - Fe - C), Silicon Manganese steel (Si-Mn-Fe-C).

Ho ea ka sebopeho se tloaelehileng kapa sa ho lahla sa lisampole tse nyane, e ka aroloa ka:Pearlitic tšepe, tšepe ea Martensitic, tšepe ea Ferritic, tšepe ea Austenitic, tšepe ea Ledeburite.

Khaello ea Tšepe ea Carbon

(1) Ho thatafala ho fokolang.Ka kakaretso, bophara bo boholo ba ho tima metsi a carbon steel quenching ke 10mm-20mm feela.

(2) Ha e le hantle, matla a tlase le ho phunya.Mohlala, σ S ea tšepe e tloaelehileng ea tšepe ea Q235 ke 235MPa, athe σ S ea tšepe e tlase ea alloy 16Mn e feta 360MPa.The σ S / σ B ea 40 tšepe ke 0.43 feela, e leng tlase haholo ho feta ea tšepe ea alloy.

(3) Ho se tsitse ha tempering.Ka lebaka la ho futsaneha tempering botsitso, k'habone tšepe ka quenching le tempering kalafo, e le ho etsa bonnete ba hore matla a phahameng ho sebelisa mocheso tlaase tempering, e le hore toughness ea tšepe e tlaase;E le ho etsa bonnete ba hore boima bo betere, matla a mocheso o phahameng oa mocheso o tlaase, kahoo lisebelisoa tse ngata tsa mochine oa carbon steel ha li phahame.

(4) Ha e khone ho finyella litlhoko tsa ts'ebetso e khethehileng.Tšepe ea carbon e hanyetsanang le oxidation, khanyetso ea kutu, ho hanyetsa mocheso, ho hanyetsa mocheso o tlase, ho hanyetsa ho roala le likarolo tse khethehileng tsa motlakase le likarolo tse ling hangata li fokola, ha li khone ho finyella litlhoko tsa ts'ebetso e khethehileng.

Khaello ea Tšepe ea Carbon

(1) Ho thatafala ho fokolang.Ka kakaretso, bophara bo boholo ba ho tima metsi a carbon steel quenching ke 10mm-20mm feela.

(2) Ha e le hantle, matla a tlase le ho phunya.Mohlala, σ S ea tšepe e tloaelehileng ea tšepe ea Q235 ke 235MPa, athe σ S ea tšepe e tlase ea alloy 16Mn e feta 360MPa.The σ S / σ B ea 40 tšepe ke 0.43 feela, e leng tlase haholo ho feta ea tšepe ea alloy.

(3) Ho se tsitse ha tempering.Ka lebaka la ho futsaneha tempering botsitso, k'habone tšepe ka quenching le tempering kalafo, e le ho etsa bonnete ba hore matla a phahameng ho sebelisa mocheso tlaase tempering, e le hore toughness ea tšepe e tlaase;E le ho etsa bonnete ba hore boima bo betere, matla a mocheso o phahameng oa mocheso o tlaase, kahoo lisebelisoa tse ngata tsa mochine oa carbon steel ha li phahame.

(4) Ha e khone ho finyella litlhoko tsa ts'ebetso e khethehileng.Tšepe ea carbon e hanyetsanang le oxidation, khanyetso ea kutu, ho hanyetsa mocheso, ho hanyetsa mocheso o tlase, ho hanyetsa ho roala le likarolo tse khethehileng tsa motlakase le likarolo tse ling hangata li fokola, ha li khone ho finyella litlhoko tsa ts'ebetso e khethehileng.